LEGATEST – Online Valve Testing

Online Valve Testing refers to the IN-SITU evaluation of valve performance under operational conditions, eliminating the need for system shutdowns.

What is Online Valve Testing?

Online Valve Testing refers to the IN-SITU evaluation of valve performance under operational conditions, eliminating the need for system shutdowns. This method enables real-time assessment of valve functionality, allowing for the identification of potential issues that could lead to system inefficiencies or failures. Furthermore, it ensures adherence to regulatory standards and compliance with industry codes, safeguarding system reliability and operational safety.

Why we need Online Valve Testing?

- Less shutdowns – Eliminates the need for system shutdowns, minimizing production interruptions and associated losses.

- No system discharges – Sustainability of the plant operation.

- Environmental Compliance – Comply with local and international environmental standards.

- Less time and cost to assemble and dissemble of pressure equipment and pipelines.

- Increase operation efficiency – Testing conducted without any interruption of the pressure system and removal of pressure equipment.

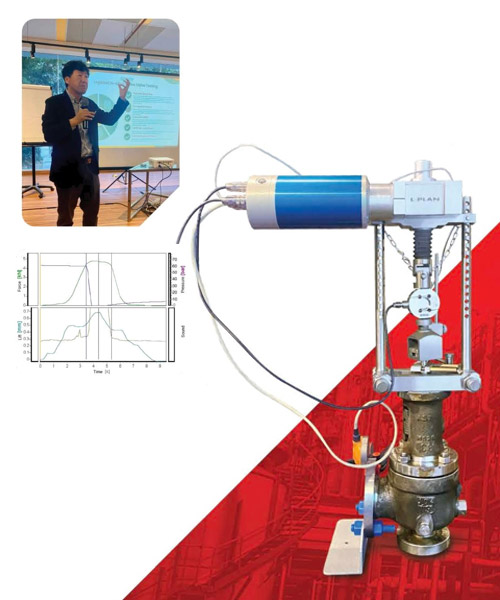

How can safety valve functions be monitored and tested with greater accuracy compared to conventional PSV testing on the test bench?

- By utilizing Legatest, a specialized high-accuracy online testing device.

- By adhering to the requirements outlined in EN ISO 4126-1:2013, Chapter 7.2.3: “The uncertainty of pressure measurement shall be within ±0.5% in the temperature range between -15°C and 60°C.”

- By overcoming limitations through innovative approaches.

- By introducing testing methods that allow evaluation during live operation.

- By leveraging in-depth knowledge of safety valve functionality and safety based behaviour (SBB).

Why is electric motor drive better then hydraulic?

- The safety valve remains open after testing. This occurs when there is insufficient pressure differential between the system’s operating pressure and the valve’s opening set point. How can this challenge be addressed?

- Determining the opening pressure can be challenging. What factors contribute to this difficulty?

- How does the motor drive impact operational safety?

- Valves are often installed in hard-to-reach locations. Testing management must therefore account for significant distances and accessibility challenges.

How can online testing with Legatest deliver exceptional efficiency?

- Legatest device can be used in potentially explosive atmospheres according to directive 94/9/EC.

- EC Type Examination Certificate Nr: SIQ 11 ATEX 134 X for Ex cones: II 2 G Ex d(ib) ib IIC T4 Gb as same as approved: Certificate of Conformity (EU).

The applicability of the Legatest device for conducting various other online testing:

With its innovative solutions and high-accuracy technology, the Legatest online safety valve testing device is able to operate in the following valve types:

- Pilot assisted safety relief valves (PASRV)

- Pressure-vacuum relief valves (PVRV)

- Pressure relief valves assisted by pneumatic control (PRVPC)

The Inspection Method – Online Valve Testing and the Legatest device are approved by L-Plan (Conformity Assessment – Inspection Body). They are all certified under:

- TUV Nord Germany

- Bureau Veritas

- Slovenian Acreditation Institute

- DET Norske Veritas

- Slovenian Quality Institute